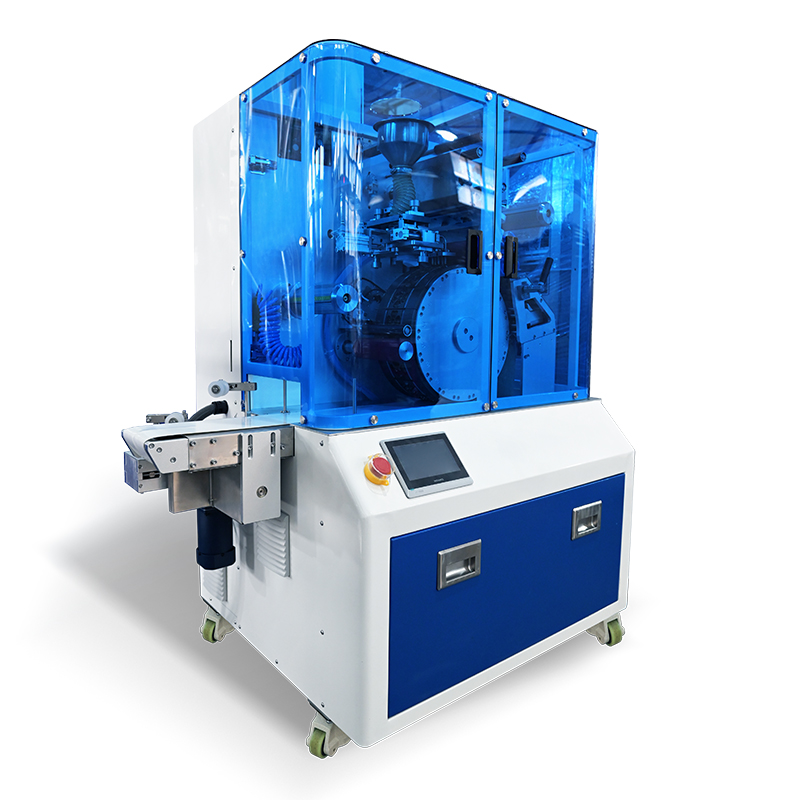

Automatic Laundry Pods Packaging Machine

The Small series adheres to the core value demands of customers,

“flexibility and convenience”. After multiple iterations and continuous optimization,it adopts the latest vacuum forming technology and slitting technology, and the equipment is stable and “durable”, making it the king of cost-effectiveness for the industry’s universal roller type laundry pods packaging equipment. It is suitable for manufacturing enterprises that are new to the pod industry to explore and expand their products and markets.

Small Water Soluble Packaging Machine Advantage

Compact Body Energy Conservation

◉ 1300×880×1600mm, minimalist installation without selecting any location, suitable for various factory layouts.

◉ The overall power of the machine is 5kw, and the independent function control is lower than 40% of the overall power, achieving low-energy operation and significant energy saving.

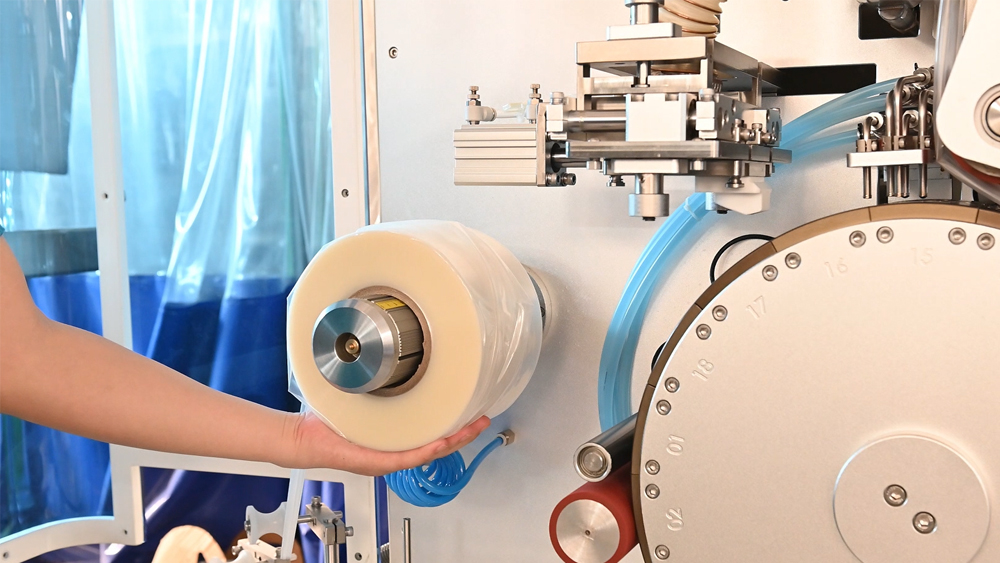

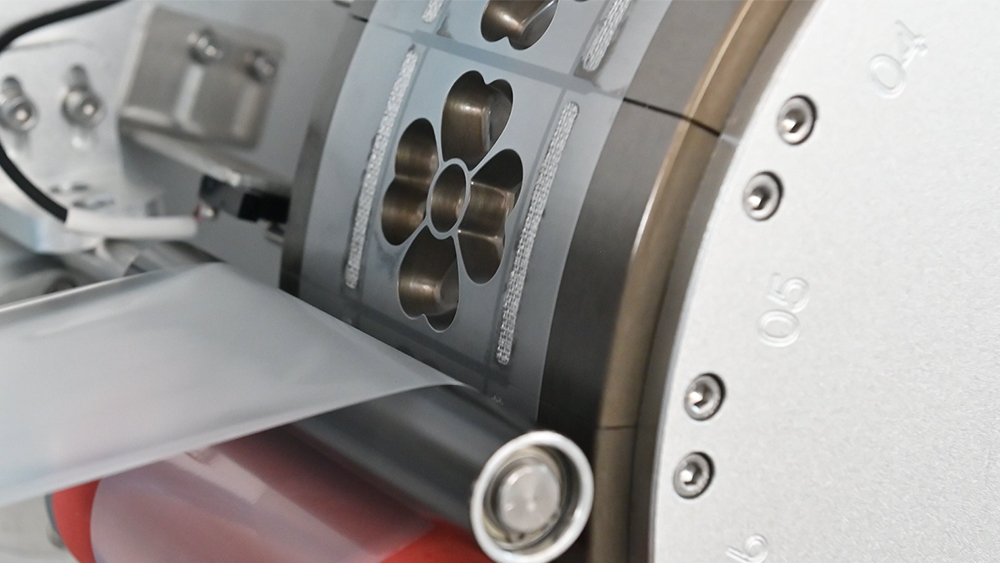

“One Out Of Two” Mold Design

6000 Pieces/Hstable Output

The main roller can be double row molded with one output and two outputs, producing a stable output of 6000 pieces per hour to meet various delivery needs. compared to large machines, 10kg can be mass-pro- duced, lexibly adapting to trial production and small order requirements.

Independent Servo Filling

◉ Powder/Granule/Liquid Full Dosage Form Optional Customization

◉ Equipped with an independent servo filling power system, single pump single head, precise control of standard liquid volume of 0.02ml.

◉ One machine for multiple uses, freely switching between filling diferent dosage forms of products to meet diverse production needs.

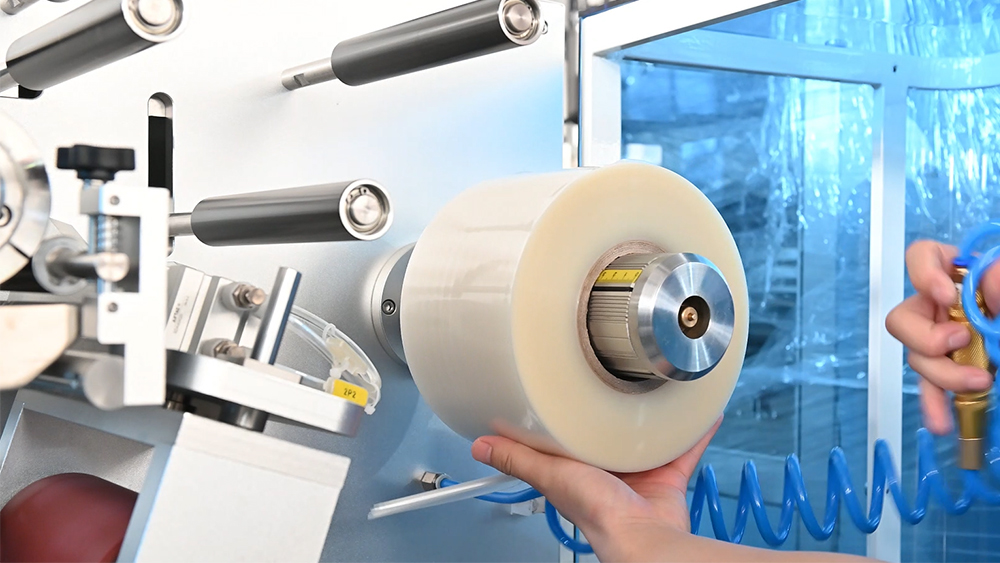

Integrated Vacuum Molding Structure Continuous And Efficient Production

Integrated vacuum molding structure, continuous packaging and integrated molding, continuous production without interruption.

Ready To Use Upon Landing Rapid Small-Scale Production

Full functional configuration, automated production process, one click start upon implementation, and quick production deployment.